Introduction: The Warehouse Receiving Bottleneck

If you’ve spent a lot of time around distribution centers (DCs) and warehouses like I have, you’ve seen it — trucks waiting hours to drop off or pick up a load. It’s worst on Sunday evenings, when some truckers park overnight and sleep in their rigs so they can be first in line Monday morning. This is obviously a significant headache for transportation providers, but it’s also a problem for the manufacturers, distributors, and retailers that ship and receive goods. That’s because when you have truckers waiting hours for a loading dock, it’s a sure sign that your supply chain is out of sync. When you don’t have enough receiving capacity, it can lead to rushing the process, skipped steps, injuries, and detention fees for excessive delay times. And if you don’t have enough capacity during crunches, there are most likely other times when you have too much capacity and workers are idle, leading to excess labor costs that hurt your bottom line. The problem is a lack of planning for warehouse receiving.

Warehouse receiving is a misunderstood source of bottlenecks in the supply chain, and it has been a problem since long before the pandemic. There is also a similar problem on the outbound shipping side, but I think it’s worse on the inbound receiving side, so I’m going to focus on receiving in this article. Outbound shipment efficiency gets more attention because it has a direct and immediate impact on the customer. But bottlenecks in receiving can wreak havoc on production and inventory plans and eventually create serious problems for your customers as well.

With all the advances in supply chain software systems, why can’t we plan better to avoid shortages and excesses of receiving capacity? Blame it on siloed supply chain processes. The supply chain planning process is typically disconnected from the process of scheduling loading docks and receiving labor.

Magnitude of the Problem: Constraints on Warehouse Receiving Capacity

Truck delay times are a good indicator of problems with warehouse receiving capacity. Such delays are caused by an inadequate number of loading docks, insufficient material handling equipment, insufficient receiving labor, or some combination of all three.

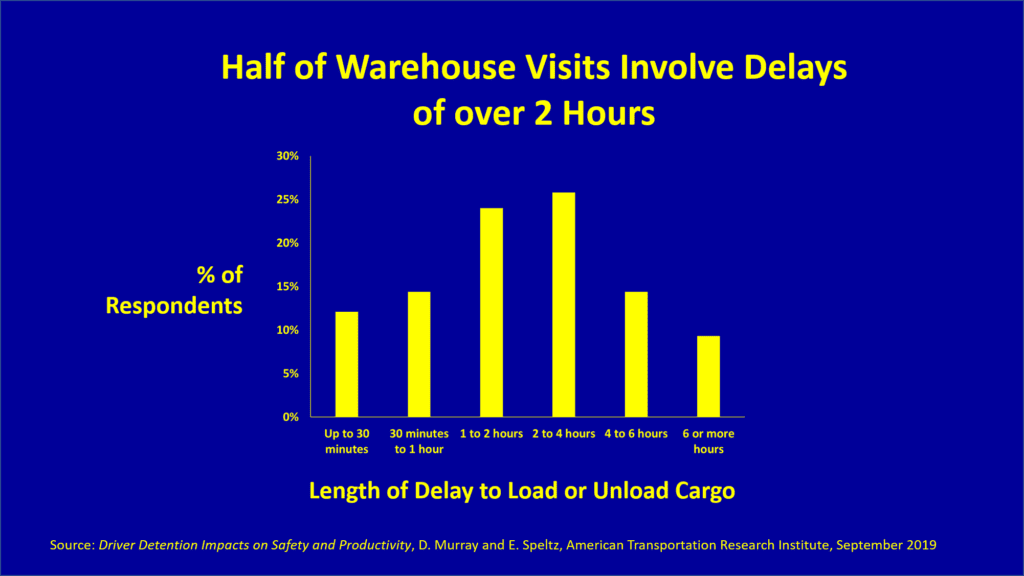

As illustrated in the chart below, a 2019 study authored by Erin Speltz and Dan Murray of the American Transportation Research Institute (ATRI) showed that nearly 26% of the time, drivers experienced waits of 2 -4 hours, over 14% of the time 4-6 hours, and over 9% of the time 6 or more hours (data combines both deliveries and pickups). Thus for 49% or about half of warehouse visits, drivers are delayed by over 2 hours. Typically, anything beyond 2 hours is considered an excessive detention, and the receiving company may incur contractual detention fees.

For transportation providers, such delays drive up labor costs, decrease truck utilization, cause problems with hours of service (HOS) compliance, and interfere with downstream pick-up and drop-off schedules. (Delays also contribute to the poor quality of life for truckers in the U.S. and thus driver shortages, but that’s a topic for another blog.)

But it’s just as big a problem for the companies receiving the goods. These companies must schedule personnel without good visibility into the schedule for inbound deliveries. To maximize receiving efficiency, inbound deliveries should occur in a smooth, predictable pattern. This isn’t possible if companies don’t have a good handle on when deliveries are going to arrive.

But What about Dock Scheduling and Labor Scheduling Software?

Companies now benefit from a number of dock scheduling software applications which allow truckers to schedule drop-offs far more efficiently than when done with phone and email. A labor scheduling system could theoretically take the output from a dock scheduling system and schedule the appropriate headcount. However, dock scheduling systems are execution systems, typically used just a few days before a delivery. These help space out deliveries during the course of a day to best make use of available docks, but if there are too many trucks that need to make deliveries on a given day, a scheduling application isn’t going to solve the problem. Furthermore, while docks can be scheduled on short notice, personnel need more advanced notice. What’s needed is a way to plan deliveries further in advance to avoid bottlenecks altogether.

Solution: Better Supply Chain Planning for Warehouse Receiving

As I stated in the introduction, supply chain planning is typically done in isolation from the process of scheduling loading docks and receiving labor. Companies plan their purchases well in advance, but they usually plan at the weekly level, meaning they specify what week they need items, but not the specific day. Therein lies the disconnect with dock scheduling.

A much better approach is to plan deliveries at a daily level, based on the available number of delivery slots in a receiving calendar. In the planning stage, you don’t need to plan the specific times and docks, but can just plan the number of deliveries on a given day, based on the receiving capacity. You may also want to set a maximum “fair share” number of deliveries for each individual supplier, so one supplier doesn’t monopolize a given day’s schedule. To accommodate days when a warehouse is closed (e.g., Sundays, holidays), you should move up deliveries as needed so you don’t run out of inventory.

By planning deliveries at the daily level, you can space multiple deliveries from multiple suppliers evenly over the course of a week to avoid crunches and lulls. Then when it’s a few days out from a planned delivery, the transportation provider or individual trucker can use a dock scheduling system to schedule the specific dock and time slot. There will be available time slots at some point in a given day because deliveries were planned to match daily capacity.

A Note about End to End Planning and the Convergence of Planning and Execution

The disconnect between supply chain planning and dock scheduling at the root of the problem described above calls out the need for end to end supply chain management and the convergence of planning and execution – both hot topics in supply chain circles these days. I wrote a previous article about a similar dynamic for transportation — how optimizing the way trucks are loaded with cargo requires taking into account truck capacity during the planning process.

It’s important to point out that simply having an integrated supply chain management suite from a single vendor does not solve the warehouse receiving problem or similar problems related to disconnected planning. The reality is that such suites consist of separate applications, for good reasons, and the fact that they are part of a suite from a single vendor does not mean that they address this or other end to end supply chain challenges. Solving such challenges requires reengineering supply chain processes and then enabling these processes with specific application functionality and integrations.

Conclusion

Warehouse receiving represents a significant source of bottlenecks in today’s supply chains because planning activities typically neglect the daily level of detail needed to efficiently schedule warehouse receiving resources. But by planning deliveries at the daily level and taking into account daily receiving capacity, companies can benefit from much more efficient receiving processes.

To Learn More

To learn how New Horizon can help you with your warehouse receiving bottlenecks, please contact us – we’d love to talk.