Introduction

Plenty has been said about supply chain resilience in the aftermath of the pandemic, but I thought it was worth taking a look at what the strategists at Boston Consulting Group (BCG) had to say about the topic in a just-published article in Harvard Business Review, “3 Steps to Prepare Your Supply Chain for the Next Crisis,” by BCG consultants Christian Schuh, Wolfgang Schnellbächer, and Daniel Weise.

The 3 Steps for Building Supply Chain Resilience

I like the article and believe it provides a valuable framework for analyzing risk and prioritizing how to build resilience in your supply chain. The authors classify risk mitigation efforts into three categories, which they detail in the article and summarize as follows:

- Creating a world-class sensing and risk-monitoring operation

- Simplifying your product portfolio

- De-risking your supply chain in terms of sourcing raw materials and components; manufacturing the products; and delivering parts to the factories and the products to the customers

The Supply Chain Risk Matrix

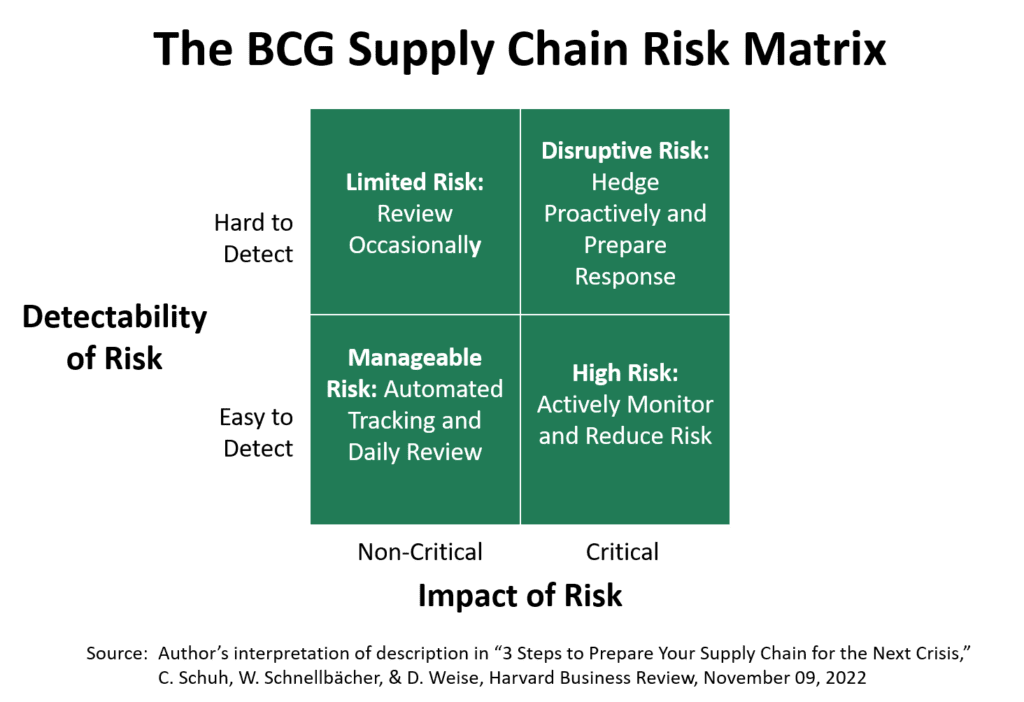

I particularly like their matrix for classifying risk. They start by considering eight essential risk categories relating to individual supplier risk, country/region risk, and industry risk. They suggest the use of Key Risk Indicators (KRIs), which allow one to quantify and compare risks. They also recommend using AI-powered sensing technology to predict potential problems. The output of all this is a classification of risks into a matrix, with different actions called for depending on which quadrant a risk falls into, per the image below. (Note, the below image is not in the article; I created it based on the description in the article.)

Critique

While I like the article, I have one issue with how they introduce the topic. The authors suggest that the pandemic was a predictable event – a “grey rhino” we could see coming rather than a “black swan” that came out of nowhere. Stuff happens, and companies need to build agility and resiliency into their supply chains to prepare for periodic disruptions such as natural disasters, economic crises, and geopolitical tensions – events we know will happen fairly frequently even if we can’t predict the details. That said, I believe the pandemic was more of a black swan. Yes, scientists have warned us of the threat of a new pandemic for decades, but the current pandemic has been an extreme event, beyond what anyone could predict, the most severe since the 1918–1920 influenza pandemic. It’s hard seeing companies justifying the investment to prepare for such long term risks, and even harder seeing Wall Street reward such investments. Preparing for these long term threats may be better suited to governments.

Conclusion

But the above point is a minor critique of what is a useful article for thinking about how to manage risk and build supply chain resilience. Too often I’ve seen supply chain risk mitigation efforts applied across the board without much thought. The BCG approach provides a framework for classifying risks so you can prioritize different types of risk and tailor your efforts accordingly.

To Learn More

To learn how New Horizon can help you build supply chain resilience, please contact us – we’d love to talk.